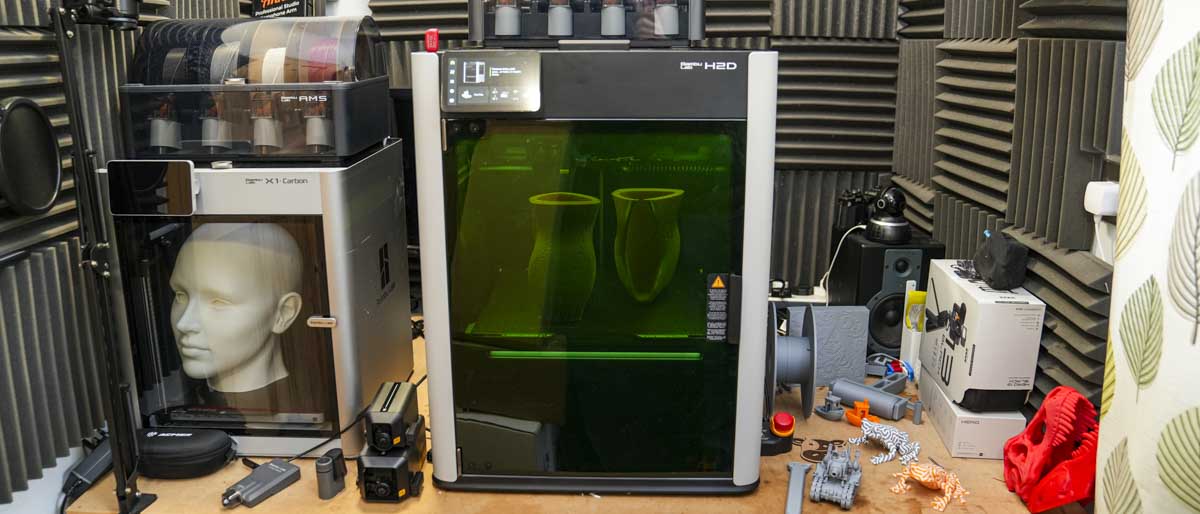

Bambu Lab H2D Launching in: Launched!

Bambu Lab’s H2D will officially launch on 25 March, and we now have all the details about this new flagship machine. This isn’t just a 3D printer – it’s a complete way to make things, combining 3D printing, laser cutting and engraving, and even digital (vinyl) cutting.

Let’s take a look at what makes this machine special and see the new technologies Bambu Lab has added.

Bambu Lab H2D: Not just a 3D printer!

The most surprising thing in the official specifications is that the H2D isn’t just a larger 3D printer with two nozzles – it’s actually a complete manufacturing platform, including:

-

Laser cutting and engraving: You can get it with 10W and 40W 455nm laser modules.

-

Digital cutting: We can cut vinyl and foil with great precision.

-

Pen drawing: It can draw and write.

This multi-purpose method is a big change for Bambu Lab. It joins together different abilities that usually need different special machines made by other companies.

The H2D seems to be Bambu Lab’s idea for a place where they can make things. It’s one device that can do different jobs, like making prototypes and products, but it will still be easy for people to use.

View fullsize

Dual-Nozzle System: What it actually does

The dual-nozzle system isn’t just for show – it actually does something useful.

-

Print more quickly in multiple colours. The dual-nozzle design reduces the number of purge cycles needed when printing with multiple colours, saving you time and filament.

-

Support material printing You can use one nozzle for the support material and the other for your model. This means you can use special support materials instead of printing supports with your model material. This should result in cleaner prints with less post-processing.

-

Printing with different materials With dual nozzles, you can print at different temperatures and diameters more easily. This means you can combine different types of materials, such as soft and hard, more easily.

According to the FAQ, the left and right hotends are the same inside and made of the same materials, so you can swap them over.

Leaked image of the 10W laser module on top of the H2D.

Dual Laser Options: 10W or 40W

The laser feature isn’t just an extra that doesn’t really do much. It’s a serious piece of kit with some impressive specs:

There are two laser options. The standard 10W laser can cut up to 5mm of basswood plywood, while the optional 40W laser can cut up to 15mm.

– Material that goes well together: Both lasers can be used on wood, rubber, metal sheets, leather, dark acrylic and stone.

Speed differences:

The fastest possible engraving speed is 400 mm/s and the maximum power is 10 W.

The fastest possible engraving speed is 1000 mm/s and the maximum power is 40 W.

– Work Area:

The dimensions are 310 mm × 270 mm, with a maximum height of 280 mm.

The dimensions of the 40W model are 310 mm × 250 mm, with a maximum height of 265 mm. Please note that this is slightly smaller due to the larger module.

The laser modules attach via pogo pins, and the H2D Laser Edition comes with built-in safety features. These include laser safety windows, meaning you don’t need to wear safety goggles, and an optional air purifier for indoor use.

If you buy the standard H2D (yes, there will be two versions), Bambu Lab will release a laser upgrade kit in June. The upgrade kit will use an external air pump rather than the built-in one in the full Laser Edition.

Example of a vinyl cutter, that moves a knife over a material to precisely cut out shapes and patterns. This will enable really cool things like creating stickers for 3D Printed RC cars!

Digital Cutting: The Surprise Feature

One of the most surprising new things about the H2D is the digital cutting feature, which seems to be Bambu Lab’s first step into the vinyl cutting market. This feature allows for:

-

Cuts very accurately using different types of blades

-

Using foils

-

Moving materials around using the BirdsEye camera system

The BirdsEye camera, along with computer vision, can achieve top-view alignment accuracy of up to 0.3mm, allowing for exact placement of cut lines. The system can also automatically arrange projects to make the most of materials and reduce waste.

This feature wasn’t mentioned in any of the previous leaks, so it was a real surprise. It makes the H2D better than we thought it would be!

Pen Plotter

The great thing about a digital (or vinyl cutter) is that instead of a blade, you can attach a pen. This makes it a pen plotter! This allows you to create or combine art in new ways.

New AMS Systems: AMS 2 Pro and AMS HT

The H2D has two new ways of handling materials:

AMS 2 Pro

Feeding is faster. The filament feeds in 60% faster thanks to a new brushless motor.

– The filament needs to dry. The system is sealed and can reach temperatures of up to 65°C when drying. Air is vented at regular intervals to keep the air circulating.

– The machine will automatically rotate while it is drying. Spools turn during the drying process to make sure the result is more even.

– RFID sync: Automatically sets the drying settings for bamboo filaments.

Dimensions: The size is 372 mm wide, 280 mm tall and 226 mm deep.

AMS HT (High Temperature)

– The drying process is done at a higher temperature. It can be used at temperatures of up to 85°C, making it perfect for working with high-performance materials.

– Bypass outlet: This is a special filament outlet for soft or brittle materials, such as TPU or wood.

– Status display: The digital display shows you the temperature, humidity and how much time is left to dry.

– Takes up less space The size is 114 mm wide, 280 mm long and 245 mm tall.

You can connect both systems together, and the H2D can support up to 4 AMS 2 Pro and 8 AMS HT units at the same time (so a total of 12 units with 24 filaments). In the most extreme scenario, all AMS units can be connected to one hotend while the other hotend uses an external spool holder, supporting up to 25 colours in a single print!

The first-generation AMS is compatible with the H2D, but it doesn’t support the drying function. The AMS Lite is not compatible because the way they are fed is different.

The AMS 2 Pro works with the X1 and P1 series printers, but you need to connect it to a power supply to use the drying feature. This will need an OTA update in April 2025.

The A1 series printers will also be updated to use AMS 2 Pro in the third quarter of 2025.

Both the X1 and the P1 will get an OTA that supports it in April 2025 as well. But you need to buy a filament buffer (and a hub if you’re using more than one AMS). The A-series will get support in the third quarter (Q3) of 2025.

Exciting Features

Beyond the headline features, the H2D includes some serious technical improvements:

-

Vision Encoder: Claims 50µm ultra-fine motion accuracy across the entire workspace using optical measurements

-

High-temperature capability: 350°C hotend and 65°C chamber heating

-

High-flow hotend: Designed for 600mm/s printing speeds (40 mm³/s flow)

-

DynaSense Extruder: Uses PMSM servo architecture with 20KHz torque/resistance sampling

-

Advanced monitoring: 15 sensors tracking the filament path from AMS to nozzle

-

AI-backed nozzle camera: Detects issues like spaghetti, nozzle clumping, and air printing

Product Configurations and Availability

The H2D will be available on March 25 in two main configurations:

H2D Laser Full Combo

-

Laser Edition Printer

-

Build Plate

-

Spool Holder

-

Accessory Box

-

10W Laser Module

-

40W Laser Module (Optional)

-

Cutting Module

-

Laser Platform

-

Cutting Platform

-

Emergency Stop Button

H2D AMS Combo

-

H2D Printer

-

Build Plate

-

Spool Holder

-

Accessory Box

-

AMS 2 Pro

While we don’t have official pricing yet, previous leaks suggest the H2D will be positioned as a premium product with prices likely around $4,000-4,500 for the full combo

Final thoughts: Who Is This For?

The H2D is clearly aimed at professional users and businesses rather than people using it for fun. The combination of 3D printing, laser cutting/engraving, and digital cutting in one machine makes it a potentially attractive all-in-one manufacturing solution for small businesses, design studios, and educational institutions.

For individual makers, the price might be a problem, but the features offered may be worth the cost for those who need different ways to make things and want to save time by having everything in one system.

The March 25th launch will reveal more details, including official pricing and availability. If you’re into high-end consumer/prosumer products, this is definitely one to watch!

What do you think about the H2D? Is this multi-purpose approach the future of desktop fabrication, or would you prefer dedicated machines for each task? Let me know what you think in the comments!

Bambu Lab H2D Full Technical Specifications

The specs were leaked via Reddit. Here they are structured for easier reading.

-

Build Volume (WxDxH)

-

Single Nozzle: 325x320x325 mm³

-

Dual Nozzle: 300x320x325 mm³

-

Two Nozzles: 350x320x325 mm³

-

-

Chassis Aluminum and Steel, Outer Frame in plastic and glass

-

Physical Dimensions: 492x514x626 mm³

-

Hotend: All Metal with Hardened Steel extruder gear and nozzle

-

Max Nozzle Temp: 350 °C

-

Included Nozzle Diameter: 0.4 mm

-

Supported Nozzle Diameters: 0.2 mm, 0.4 mm, 0.6 mm, 0.8 mm

-

Filament Cutter: Built-in

-

Filament Diameter: 1.75 mm

-

Extruder Motor: Bambu Lab High-precision Permanent Magnet Synchronous Motor

-

Heatbed: Flexible Steel Plate (Textured PEI Plate)

-

Supported Plate Types: Textured PEI, Smooth PEI

-

Max Heatbed Temperature: 120 °C

-

Print Max Speed: 1000 mm/s

-

Max Acceleration: 20,000 mm/s²

-

Hotend Max Flow Rate: 40mm³/s

-

Active Chamber Heating

-

Max Chamber Temp: 65 °C

-

Pre-filter Grade G3

-

HEPA Filter Grade H12

-

Activated Carbon Filter: Granulated Coconut Shell

-

VOC Filtration: “Superior”

-

Particulate Filtration: Yes

-

Cooling: Part cooling, Mainboard, Chamber exhaust, Chamber circulation, Auxiliary Part Cooling.

-

FIlament Support:

-

PLA, PETG, TPU, PVA, BVOH (Optimal)

-

ABS, ASA, PC, PA, PET (Superior)

-

Carbon/Glass Fiber Reinforced PLA,PETG, PA, PET, PC, ABS,ASA (Superior)

-

PPA-CF/GF, PPS, PPS-CF/GF (Ideal)

-

Technical Specs Continued (sensors, Slicer, network)

-

Live View Camera: Built-in; 1920×1080

-

Nozzle Camera: Built-in; 1920×1080

-

BirdsEye Camera: Built-in; 3264×2448

-

Toolhead Camera: Built-in; 1920×1080

-

Door Sensor: Yes

-

Filament Run Out Sensor: Yes

-

Filament Tangle Sensor: Yes

-

Filament Odometry: Supported with AMS

-

Power Loss Recovery: Yes

-

Max Power: 2200 W@220 V / 1320 W@110 V

-

Average Power: 1050 W@220 V / 1050 W@110 V

-

-

Touchscreen 5-inch 1280×720

-

Storage: Built-in 8 GB EMMC and USB Port

-

Control Interface: Touchscreen, mobile App, PC App

-

Motion Controller: Dual-core Cortex-M4 and Single-core Cortex-M7

-

Application Processor: Quad-core 1.5 GHz ARM A7

-

Neural Processing Unit: 2 TOPS

-

Slicer: Bambu Studio; supports third-party slicers (e.g., Cura, PrusaSlicer). Some advanced features may not work on 3rd-party.

-

Supported Operating System: MacOS, Windows

-

Ethernet: No

-

Wireless Network: Wi-Fi

-

Network Kill Switch: Not Available

-

Removable Network Module: Not Available

-

802.1X Network Access Control: Not Available

-

Wi-Fi: 2.4Ghz and 5Ghz

Technical Specs: H2D Laser Module

10W Laser Module

-

Laser Type: Semiconductor Laser

-

Laser Wavelength: Engraving Laser: 455 nm ± 5 nm Blue Light

-

Height Measuring Laser: 850 nm ± 5 nm Infrared Light

-

Laser Power: 10 W ± 1 W

-

Laser Spot Dimension: 0.03 mm x 0.14 mm

-

Max Engraving Speed 400 mm/s

-

Max Cutting Thickness: 5 mm (Basswood Plywood)

-

Laser Safety Class for Laser Module: Class 4

-

Overall Laser Safety Class: Class 1

-

Engraving Area: 310 mm x 270 mm

-

Processing Height Range: 0 mm – 280 mm

-

XY Positioning Method: Visual Positioning

-

XY Positioning Accuracy: < 0.3 mm

-

Z Height Measuring Method: Micro Lidar (Accuracy ± 0.1 mm)

-

Flame Detection: Supported

-

Temperature Detection: Supported

-

Door Sensor: Supported

-

Laser Module Installation Detection: Supported

-

Engraving Timelapse: Supported

-

Safety Key: Included

-

Air Pump: Built-in; 30 kPa, 30 L/min

-

Ventilation Pipe Adapter Outer Diameter: 100 mm

-

Supported Material Type: Wood, rubber, metal sheet, leather, dark acrylic, stone, and more

40W Laser Module

-

Laser Type: Semiconductor Laser

-

Laser Wavelength: Engraving Laser: 455 nm ± 5 nm Blue Light

-

Height Measuring Laser: 850 nm ± 5 nm Infrared Light

-

Laser Power: 40 W ± 2 W

-

Laser Spot Dimension: 0.14 mm x 0.2 mm

-

Max Engraving Speed 1000 mm/s

-

Max Cutting Thickness: 15 mm (Basswood Plywood)

-

Laser Safety Class for Laser Module: Class 4

-

Overall Laser Safety Class: Class 1

-

Engraving Area: 310 mm x 250 mm

-

Processing Height Range: 0 mm – 265 mm

-

XY Positioning Method: Visual Positioning

-

XY Positioning Accuracy: < 0.3 mm

-

Z Height Measuring Method: Micro Lidar (Accuracy ± 0.1 mm)

-

Flame Detection: Supported

-

Temperature Detection: Supported

-

Door Sensor Supported

-

Laser Module Installation Detection: Supported

-

Engraving Timelapse: Supported

-

Safety Key: Included

-

Air Pump: Built-in; 30 kPa, 30 L/min

-

Ventilation Pipe Adapter Outer Diameter: 100 mm

-

Supported Material Type: Wood, rubber, metal sheet, leather, dark acrylic, stone, and more

H2D Cutting Module Technical Specifications

-

Cutting Area: 300 x 285 mm²

-

Drawing Area: 300 x 255 mm²

-

Supported Pen Diameter: 10.5 mm – 12.5 mm

-

Cutting Mat Type: LightGrip and StrongGrip Cutting Mats

-

Blade Type: 45° x 0.35 mm

-

Blade Pressure Range: 50 gf-600 gf

-

Max Cutting Thickness: 0.5 mm

-

Blade and Pen Recognition: Supported

-

Cutting Mat Type Detection: Supported

-

Supported Image Type: Bitmap and Vector Images

-

Supported Material Type: Paper, vinyl, leather, and more